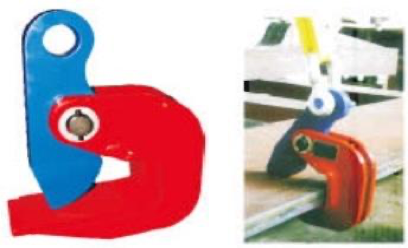

Horizontal Steel Plate Lifting Clamp

■ Used for lifting steel plates in the horizontal direction. Indicates the maximum load capacity per clamp when used in pairs. A balance beam must be added if the steel plate is excessively long to ensure stability.

■ 2 times the Working Load Limit; Breaking Load: 4 times the Working Load Limit.

■ Carefully read the operation manual before use; Overloading or independent use of a single clamp is strictly prohibited; Regularly inspect the clamp body, pins, and balance beam for wear.

| Product | WLL | Steel plate thickness | A | B | C | D | t | φd | Self weight |

|---|---|---|---|---|---|---|---|---|---|

| type | t | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) |

| DHQ2 | 2 | 1~20 | 127 | 156 | 56 | 29 | 16 | 22 | 2.12 |

| DHQ3 | 3 | 1~30 | 152 | 190 | 64 | 31 | 18 | 28 | 3.4 |

| DHQ5 | 5 | 20~60 | 220 | 293 | 70 | 54 | 20 | 34 | 8.5 |

| DHQ8 | 8 | 50~100 | 277 | 375 | 86 | 59 | 25 | 40 | 16.2 |

| DHQ10 | 10 | 60~125 | 296 | 421 | 86 | 66 | 25 | 50 | 20.2 |

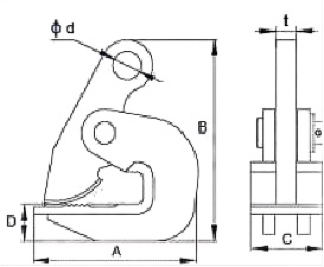

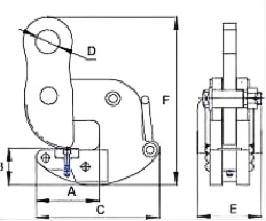

Vertical Steel Plate Lifting Clamp

■ Used for lifting steel plates in the vertical direction. It can be operated with a single clamp or in pairs.Single clamp: Maximum load capacity indicated per clamp.Paired use: Total load must be evenly distributed between clamps.

■ Only single-plate lifting is allowed. Stacking multiple plates is strictly forbidden.Avoid collisions with other objects during lifting.

■ Operating Procedure. step1 is clamping: Lift the locking handle upward to compress the spring and secure the jaws.step 2 is releasing:Press the locking handle downward to release the spring and detach the clamp from the steel plate.

■ Clamp Teeth Material: Alloy steel, treated with Mesh Belt Furnace Oxidation Heat Treatment to achieve high hardness and toughness.

■ Read the operation manual thoroughly before use.Strictly prohibited:Overloading;Single-clamp overload;Multi-plate stacking.Regularly inspect:Wear on clamp teeth;Spring elasticity;Reliability of the locking mechanism.

| Product | WLL | Steel plate thickness | A | B | C | D | E | F | G | H | I | Test mark | Self weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| type | t | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | kg |

| DSQ1 | 1 | 1~16 | 59 | 12 | 16 | 45 | 32 | 122 | 73 | 277.5 | 155 | 50 | 3.7 |

| DSQ2 | 2 | 1~22 | 61 | 16 | 23 | 55 | 45 | 165 | 88 | 340 | 190 | 55 | 6.3 |

| DSQ3 | 3 | 5~30 | 72 | 16 | 28 | 60 | 55 | 195 | 110 | 374 | 227 | 70 | 10.5 |

| DSQ5 | 5 | 16~50 | 82 | 20 | 33 | 70 | 70 | 250 | 135 | 458 | 275 | 90 | 19.3 |

| DSQ8 | 8 | 40~80 | 100 | 25 | 40 | 80 | 91 | 345 | 175 | 610 | 370 | 130 | 40 |

| DSQ12 | 12 | 50~90 | 107 | 28 | 45 | 90 | 105 | 430 | 182 | 635 | 380 | 150 | 55 |

| DSQ16 | 16 | 60~100 | 107 | 41 | 50 | 100 | 115 | 455 | 200 | 650 | 410 | 160 | 63 |

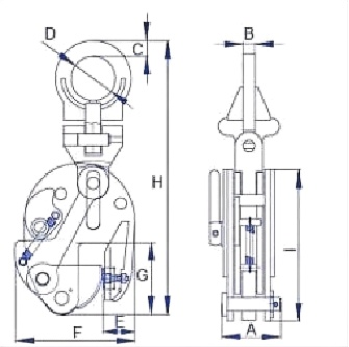

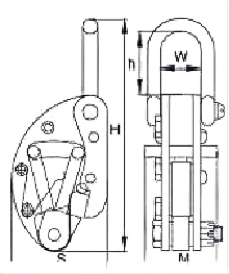

Oil Drum Clamp

■ Used for lifting oil drums vertically. It can be operated with a single clamp or in pairs.

■ Single clamp: Maximum load capacity per clamp.Total load must be evenly distributed between clamps.

■ Avoid collisions with other objects.Proof Test Load: 1.5 times the Working Load Limit (1.5 × WLL);Breaking Load: 3 times the Working Load Limit (3 × WLL).

■ Read the operation manual thoroughly before use.Strictly prohibited:Overloading;Partial loading (e.g., tilted drum lifting).Regular inspections required:Wear on clamp body structure;Condition of locking mechanisms;Integrity of connecting components.

| Product | WLL | Steel plate thickness | A | B | C | D | E | F | Self weight |

|---|---|---|---|---|---|---|---|---|---|

| type | (t) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | kg |

| DFQ1.5 | 1.5 | 1~20 | 80 | 43 | 153 | 30 | 80 | 205 | 5.2 |

| DFQ2.5 | 2.5 | 1~30 | 105 | 52 | 190 | 35 | 90 | 270 | 8.7 |

| DFQ5 | 5 | 10~40 | 136 | 82 | 247 | 46 | 114 | 380 | 25 |

| DFQ10 | 10 | 20~50 | 160 | 85 | 300 | 60 | 129 | 410 | 35 |

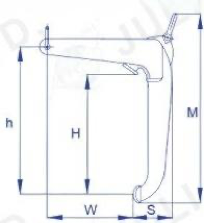

Rollover Clamp

■ Used for lifting steel plates in the horizontal direction and performing rollover operations on steel plates and section steel.

■ During Lifting should avoid collisions with other objects.Can be used with a single clamp. Working Load Limit (WLL) indicates the maximum load capacity per clamp.

■ Horizontal Lifting Requirement:A balance beam must be installed to ensure load stability.

■ Proof Test Load: 2 times the Working Load Limit (2 × WLL);Breaking Load: 4 times the Working Load Limit (4 × WLL).

■ Read the operation manual carefully before use.Integrity of the clamp body structure;Connection points of the balance beam;Condition of the locking mechanisms.

| Product | WLL | Opening | H | h | M | S | W | Self weight |

|---|---|---|---|---|---|---|---|---|

| type | (t) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | kg |

| YQC0.6 | 0.6 | 0~30 | 350 | 420 | 570 | 105 | 260 | 6.5 |

Oil Drum Clamp (DYQ)

■ Used for lifting oil drums in both horizontal and vertical directions. It can be operated with a single clamp or in pairs.

■ Single clamp: Maximum load capacity per clamp.Paired use: Total load must be evenly distributed between clamps.During Lifting:Avoid collisions with other objects.

■ Proof Test Load: 2 times the Working Load Limit (2 × WLL);Breaking Load: 4 times the Working Load Limit (4 × WLL).

■ Read the operation manual carefully before use.

■ Strictly prohibited:Overloading;Partial loading (e.g., tilted drum lifting).Regular inspections required:Integrity of clamp body structure;Condition of locking mechanisms;Wear on connecting components.

| Product | WLL | Opening | H | h | M | S | W | Self weight |

|---|---|---|---|---|---|---|---|---|

| type | (t) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) |

| DYQ0.2 | 0.2 | 2~10 | 188 | 60 | 60 | 80 | 35 | 1 |

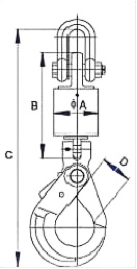

Oil Field Shackle Hook

■ Self-lock hook allows 360° free rotation under no-load or loaded conditions, adapting to complex working angles.

■ Proof Test Load: 2 times the Working Load Limit (2 × WLL);Breaking Load: 3.5 times the Working Load Limit (3.5 × WLL).

■ Ensure the hook’s locking mechanism is in the free state during rotation to avoid forced jamming.Strictly prohibited:Overloading;Using deformed or worn shackle hooks.Regular inspections required:Integrity of the hook body;Condition of pins;Reliability of the locking device.

| WLL | A | B | C | D | Shackle working load | Hook working load | Self weight |

|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (t) | (t) | (kg) |

| 5 | 96 | 229 | 487.8 | 50 | 6.5 | 5.4 | 13.8 |

| 8 | 128 | 315 | 628.6 | 60 | 8.5 | 8.2 | 19.6 |

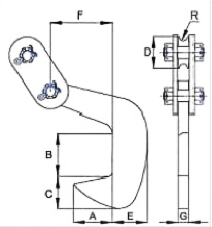

Single Plate Clamp

■ Used for lifting single or multiple steel plates in the horizontal direction.

■ Working Load Limit (WLL):Defined as the maximum load capacity of one pair of clamps at a 60° lifting angle.

■ Four clamps must be used simultaneously and coordinated with a balance beam.Avoid collisions with other objects during lifting.Equipped with an automatic release function for safe disengagement.

■ Read the operation manual thoroughly before use.Strictly prohibited:Overloading;Lifting without a balance beam;Exceeding WLL at angles other than 60°.Regular inspections required:Wear on clamp teeth;Responsiveness of the locking mechanism;Stability of balance beam connection points.

| Product | WLL | Steel plate thickness | A | B | C | D | E | F | G | R | Self weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| type | t | (mm) | (mm) | (mm) | (mm | (mm) | (mm) | (mm) | (mm) | (mm) | kg |

| DCQA3 | 3 | 30~90 | 102 | 90 | 68 | 78 | 84 | 168 | 25 | 9 | 12 |

| DCQA5 | 5 | 40~100 | 108 | 100 | 73 | 88 | 97 | 172 | 30 | 11 | 15 |

| DCQA8 | 8 | 80~140 | 110 | 127.5 | 80 | 110 | 124 | 240 | 30 | 15 | 21.2 |

| DCQA10 | 10 | 90~150 | 122 | 155 | 85 | 120 | 141 | 260 | 35 | 15 | 27 |

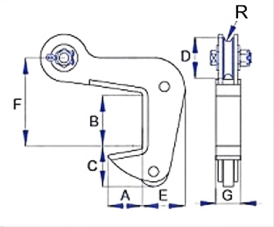

Double Plate Lifting Clamp

■ Used for lifting single or multiple steel plates in the horizontal direction.

■ Working Load Limit (WLL):Defined as the maximum load capacity of one pair of clamps at a 60° lifting angle.

■ Four clamps must be used simultaneously and coordinated with a balance beam.Avoid collisions with other objects during lifting.Equipped with an automatic release function for safe disengagement.

■ Read the operation manual thoroughly before use.Strictly prohibited:Overloading;Lifting without a balance beam;Exceeding WLL at angles other than 60°.Regular inspections required:Wear on clamp teeth;Responsiveness of the locking mechanism;Stability of balance beam connection points.

| Product | WLL | Steel plate thickness | A | B | C | D | E | F | G | R | Self weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| type | t | (mm) | (mm) | (mm) | (mm | (mm) | (mm) | (mm) | (mm) | (mm) | kg |

| DCQB4 | 4 | 40~100 | 72 | 102 | 70 | 74 | 82 | 179 | 60 | 10 | 7 |

| DCQB6 | 6 | 40~120 | 91 | 129 | 89 | 100 | 107 | 263 | 73 | 12 | 14 |

| DCQB10 | 10 | 120~210 | 134 | 213 | 133 | 130 | 148 | 357 | 90 | 15 | 32 |