T(8)grade chain

The breaking strength of T(8)-grade high-strength chains is ≥ 80MPa.

The chains are made of alloy steel and have undergone heat treatment. The elongation rate at break is ≥ 17%. The national implementation standard is: GB/T 24816-2009.

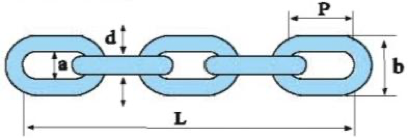

| Specification | Applicability | Chain | Width (m) | Weight per meter | Working load | WTest load | Minimum breaking load | |

|---|---|---|---|---|---|---|---|---|

| (m) | mm | in | a | b | (Kg) | (KN) | (KN) | (KN) |

| 6×18 | 6 | 7/32 | 7.5 | 21 | 0.79 | 10 | 20 | 45.2 |

| 8×24 | 7 | 5/16 | 10 | 28 | 1.38 | 15 | 30 | 80.4 |

| 10×30 | 10 | 3/8 | 12.5 | 35 | 2.2 | 25 | 50 | 125 |

| 12×36 | 12 | 7/16 | 15 | 42 | 3.1 | 35 | 70 | 181 |

| 13×39 | 13 | 1/2 | 16.3 | 46 | 3.8 | 40 | 80 | 214 |

| 14×42 | 14 | 1/2 | 18 | 49 | 4.13 | 50 | 100 | 250 |

| 15×46 | 15 | 3/5 | 20 | 52 | 5.17 | 55 | 110 | 280 |

| 16X48 | 16 | 5/8 | 20 | 56 | 5.63 | 60 | 120 | 320 |

| 18×54 | 18 | 23/32 | 23 | 63 | 6.85 | 80 | 160 | 410 |

| 19×57 | 19 | 3/4 | 23.7 | 63.2 | 7.7 | 90 | 180 | 450 |

| 20×60 | 20 | 3/4 | 25 | 70 | 8.6 | 100 | 200 | 500 |

| 22×66 | 22 | 7/8 | 28 | 77 | 10.2 | 120 | 240 | 610 |

| 24×72 | 24 | 15/16 | 32 | 82 | 12.78 | 140 | 280 | 720 |

| 26×78 | 26 | 1 | 35 | 91 | 14.87 | 170 | 340 | 850 |

| 30×90 | 30 | 13/16 | 38 | 105 | 19.6 | 220 | 440 | 1130 |

| 32×96 | 32 | 11/4 | 40 | 106 | 22.29 | 250 | 500 | 1286 |

| 34X126 | 34 | 13/8 | 42.5 | 109 | 22.7 | 363 | 870 | 1450 |

S(6)grade chain

| Chain diameter | Ultimate outer length of the chain L | Chain link at the non-welded joint | Ultimate working load | Verification force borne by the whole chain | Minimum breaking force | Weight per meter | ||

|---|---|---|---|---|---|---|---|---|

| (dn) | Max 5dn | Min 4.75dn | Minimum outer width W | Minimum inner width W | (t) | (KN) | (KN) | (Kg) |

| 5 | 25 | 24 | 18 | 6.3 | 0.63 | 12.4 | 24.8 | 0.54 |

| 6.3 | 32 | 30 | 22 | 7.9 | 1 | 19.7 | 39.4 | 0.88 |

| 7.1 | 36 | 34 | 25 | 8.9 | 1.25 | 25 | 50 | 1.1 |

| 8 | 40 | 38 | 28 | 10 | 1.6 | 31.7 | 63.4 | 1.43 |

| 9 | 45 | 43 | 32 | 11.3 | 2 | 40.1 | 80.2 | 1.86 |

| 10 | 50 | 47 | 35 | 12.5 | 2.5 | 49.5 | 99 | 2.28 |

| 11.2 | 56 | 53 | 39 | 14 | 3.2 | 63 | 126 | 2.82 |

| 12.5 | 63 | 59 | 44 | 15.7 | 4 | 79 | 158 | 3.5 |

| 14 | 70 | 66 | 49 | 18 | 5 | 99 | 198 | 4.32 |

| 16 | 80 | 76 | 56 | 20 | 6.3 | 127 | 254 | 5.67 |

| 18 | 90 | 85 | 63 | 23 | 8 | 161 | 322 | 7.4 |

| 20 | 100 | 95 | 70 | 25 | 10 | 198 | 396 | 9.2 |

| 22.4 | 112 | 106 | 78 | 28 | 12.5 | 249 | 498 | 11.3 |

| 25 | 125 | 119 | 88 | 32 | 16 | 314 | 628 | 14.7 |

| 28 | 140 | 133 | 98 | 35 | 20 | 393 | 786 | 17.6 |

| 32 | 160 | 152 | 112 | 40 | 25 | 507 | 1014 | 24.2 |

| 36 | 180 | 171 | 126 | 45 | 32 | 642 | 1284 | 31.2 |

| 40 | 200 | 190 | 140 | 50 | 40 | 792 | 1584 | 38.7 |

| 45 | 225 | 214 | 158 | 57 | 50 | 1002 | 2004 | 48.8 |