Pressed wire rope rigging

The pressed wire rope rigging is made of the world's highest quality wire ropes, which are processed and formed through professional deep-processing equipment for wire ropes and advanced processing techniques. It can achieve an easy connection with the lifted object, and is a safe and practical special hoisting tool for lifting, shifting and handling heavy objects. It is characterized by high temperature resistance, wear resistance, convenient use and large load-bearing capacity, and is widely used in industries such as machinery, metallurgy, shipbuilding, petroleum, fishery, forestry, drilling, coal mining, ports, etc.

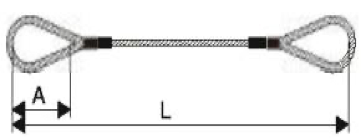

The diameter range of the pressed wire rope: φ6mm - 500mm. For the pressed wire rope rigging with a diameter of over φ90, two aluminum alloy pressing heads are pressed at each end.

The breaking load of the rigging is 5 times the working load.

The working load varies according to the different specifications of the wire rope. The working load can be calculated according to the wire rope required by the user.

| Nominal diameter | Rated load(KN) | Approximate length of the sleeve-A | |

|---|---|---|---|

| (mm) | Fiber core | Steel core | (mm) |

| 6 | 3.2 | 3.4 | 180 |

| 7 | 4.3 | 4.7 | 190 |

| 8 | 5.7 | 6.1 | 210 |

| 9 | 7.2 | 7.8 | 230 |

| 10 | 8.9 | 9.6 | 230 |

| 11 | 11 | 12 | 250 |

| 12 | 13 | 14 | 260 |

| 13 | 15 | 16 | 260 |

| 14 | 17 | 19 | 280 |

| 16 | 23 | 24 | 320 |

| 18 | 29 | 31 | 360 |

| 20 | 35 | 38 | 400 |

| 22 | 43 | 46 | 440 |

| 24 | 51 | 55 | 480 |

| 26 | 60 | 65 | 520 |

| 28 | 69 | 75 | 560 |

| 30 | 80 | 86 | 600 |

| 32 | 91 | 98 | 640 |

| 34 | 102 | 110 | 680 |

| 36 | 115 | 124 | 720 |

| 38 | 128 | 138 | 760 |

| 40 | 142 | 153 | 800 |

| 42 | 157 | 169 | 840 |

| 44 | 172 | 185 | 880 |

| 46 | 187 | 203 | 920 |

| 48 | 203 | 220 | 960 |

| 50 | 221 | 240 | 1000 |

| 52 | 239 | 259 | 1040 |

| 54 | 258 | 279 | 1080 |

| 56 | 277 | 301 | 1120 |

| 58 | 298 | 322 | 1160 |

| 60 | 319 | 344 | 1200 |

| 64 | 362 | 392 | 1280 |

| 66 | 385 | 418 | 1320 |

| 68 | 349 | 413 | 1360 |

| 70 | 370 | 437 | 1400 |

| 72 | 391 | 463 | 1440 |

| 74 | 413 | 489 | 1480 |

| 76 | 436 | 516 | 1520 |

| 78 | 459 | 543 | 1560 |

| 80 | 483 | 571 | 1600 |

| 82 | 507 | 600 | 1640 |

| B4 | 532 | 630 | 1680 |

| 86 | 558 | 660 | 1720 |

| 88 | 5B4 | 691 | 1760 |

| 90 | 611 | 723 | 1800 |

| 92 | 639 | 756 | 1840 |

| 94 | 667 | 789 | 1880 |

| 96 | 695 | 323 | 1920 |

| 98 | 725 | 857 | 1960 |

| 100 | 755 | 393 | 2000 |

Complete Set of Pressed Wire Rope Rigging

■ The specification of the wire rope used for the working load in this table is: 6×37+FC-1670;

■ The breaking load of the rigging is 5 times the working load;

■ The working load varies according to the different specifications of the wire rope. The working load can be calculated according to the wire rope required by the customer;

■ In the case that the customer has no special requirements, for two-leg riggings, the load within the range of 0°-90° is preferentially selected, and for three-leg or four-leg riggings, the load within the range of 0°-45° is preferentially selected;

■ The matched lifting rings and hooks should be used with reference to the corresponding technical parameters.

■ The Execution Standard for Wire Rope Rigging: GB/T16762-2009

| Complete set of wire rope rigging |

|||||

|---|---|---|---|---|---|

| Nominal diameter | Rated load | Rated load(KN) | Rated load(KN) | ||

| (mm) | (KN) | 0°-90° | 90° -120° | 0-45° | 45°-60° |

| 6 | 2.7 | 3.7 | 2.7 | 5.6 | 4 |

| 7 | 3.6 | 5 | 3.6 | 7.6 | 5.4 |

| 8 | 4.7 | 6.6 | 4.7 | 9.9 | 7.1 |

| 9 | 6 | 8.4 | 6 | 12.6 | 9 |

| 10 | 7.4 | 10.4 | 7.4 | 15 | 11 |

| 11 | 8.9 | 13 | 9 | 19 | 13 |

| 12 | 11 | 15 | 11 | 22 | 16 |

| 13 | 12 | 17 | 12 | 26 | 19 |

| 14 | 14 | 20 | 14 | 30 | 22 |

| 16 | 19 | 26 | 19 | 40 | 28 |

| 18 | 24 | 33 | 24 | 50 | 36 |

| 20 | 30 | 41 | 30 | 62 | 44 |

| 22 | 36 | 50 | 36 | 75 | 54 |

| 24 | 42 | 59 | 42 | 89 | 64 |

| 26 | 50 | 70 | 50 | 105 | 75 |

| 28 | 58 | 81 | 58 | 122 | 87 |

| 32 | 76 | 106 | 76 | 159 | 113 |

| 36 | 96 | 134 | 96 | 201 | 144 |

| 40 | 118 | 165 | 118 | 248 | 177 |

| 44 | 143 | 200 | 143 | 300 | 214 |

| 48 | 170 | 237 | 170 | 356 | 254 |

| 52 | 200 | 279 | 200 | 419 | 299 |

| 56 | 231 | 323 | 231 | 485 | 347 |

| 60 | 266 | 372 | 266 | 558 | 398 |

| 64 | 302 | 422 | 302 | 633 | 452 |

| 66 | 321 | 449 | 321 | 674 | 482 |

| 68 | 291 | 407 | 291 | 610 | 436 |

| 70 | 308 | 431 | 308 | 647 | 462 |

| 72 | 326 | 456 | 326 | 684 | 489 |

| 74 | 344 | 482 | 344 | 723 | 516 |

| 76 | 363 | 508 | 363 | 763 | 545 |

| 78 | 383 | 536 | 383 | 803 | 574 |

| 80 | 402 | 563 | 402 | 845 | 604 |

| 82 | 423 | 592 | 423 | 888 | 634 |

| 84 | 444 | 621 | 444 | 932 | 666 |

| 86 | 465 | 651 | 465 | 977 | 699 |

| 88 | 487 | 682 | 487 | 1022 | 730 |

| 90 | 509 | 713 | 509 | 1069 | 764 |

| 92 | 532 | 745 | 532 | 1118 | 798 |

| 94 | 556 | 7T8 | 556 | ||

| 96 | 579 | 811 | 579 | ||

| 98 | 604 | 845 | 604 | ||

| 100 | 629 | 880 | 629 | ||

| 104 | 680 | 952 | 680 | ||

| 108 | 707 | 1027 | 733 | ||

| 110 | 761 | 1065 | 761 | ||

| 112 | 789 | 1104 | 789 | ||