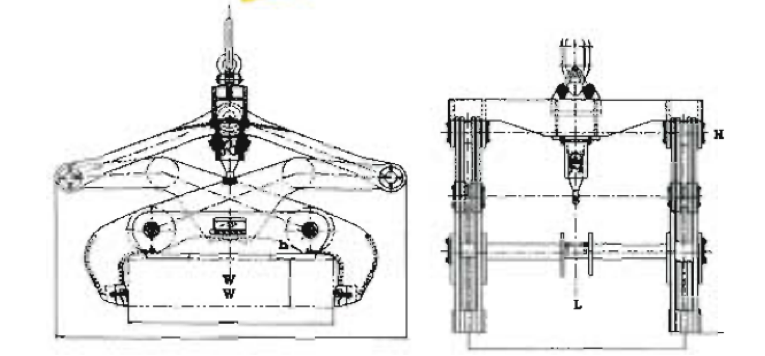

Mechanical Slab Lifting Clamp

■ This slab clamp utilizes a self-locking lever mechanism to securely grip slabs without external power, ensuring reliable clamping force and agile operation.

■ Opening/closing actuator is constructed with high-strength wear-resistant alloy steel , delivering precision movement and extended service life.

■ Available in fixed-type and stepless height-adjustable configurations, compatible with slabs of 200-300mm thickness and stacked layers ≤5

■ Overhead crane interface supports flange connection (DIN 15411) or lifting lug (FEM 1.001), customization per client's EOT crane structural parameters.

| WLL | Application | Height of | Span (L) | Max.dimension( mm) | |

|---|---|---|---|---|---|

| (t) | scope W (mm) | leg H (mm) | (mm) | W | H |

| 5 | 450-600 | 150 | 800 | 1200 | 1800 |

| 5 | 650-1000 | 250 | 800 | 1500 | 2300 |

| 8 | 150-450 | 250 | 1200 | 2000 | 2400 |

| 8 | 450-600 | 300 | 1200 | 1600 | 2500 |

| 8 | 450-750 | 300 | 1200 | 600 | 2200 |

| 10 | 450-900 | 300 | 1500 | 1900 | 2600 |

| 10 | 650-1000 | 300 | 1500 | 2000 | 2600 |

| 10 | 700-1100 | 300 | 1500 | 1900 | 2600 |

| 12 | 450-750 | 300 | 2000 | 1800 | 2400 |

| 12 | 235-800 | 300 | 2000 | 2300 | 3000 |

| 16 | 600-1100 | 450 | 2500 | 2400 | 3100 |

| 16 | 850-1250 | 300 | 2500 | 2000 | 3000 |

| 20 | 800-1300 | 300 | 3000 | 2200 | 3400 |

| 20 | 950-1400 | 300 | 3000 | 2500 | 3500 |

| 20 | 1100-1600 | 300 | 3000 | 2400 | 3700 |

| 25 | 1000-1600 | 600 | 3000 | 3000 | 3900 |

| 25 | 1250-1750 | 450 | 3000 | 2800 | 3900 |

| 32 | 700-1350 | 450 | 3000 | 2900 | 4000 |

| 32 | 750-1400 | 450 | 3000 | 2800 | 4200 |

| 32 | 650-1500 | 450 | 3000 | 3400 | 4600 |

| 32 | 900-2150 | 600 | 3000 | 4400 | 6000 |

| 32 | 1000-2300 | 600 | 3000 | 4700 | 6300 |

| 40 | 850-1600 | 450 | 4000 | 3500 | 4900 |

| 40 | 1250-1750 | 450 | 3500 | 3000 | 3000 |

| 40 | 1600-2150 | 450 | 3500 | 3300 | 4300 |

| 50 | 1250-2150 | 450 | 4000 | 4000 | 5600 |

| 50 | 1850-2500 | 450 | 4000 | 3800 | 5000 |

| 63 | 2050-2750 | 600 | 4000 | 4300 | 5800 |

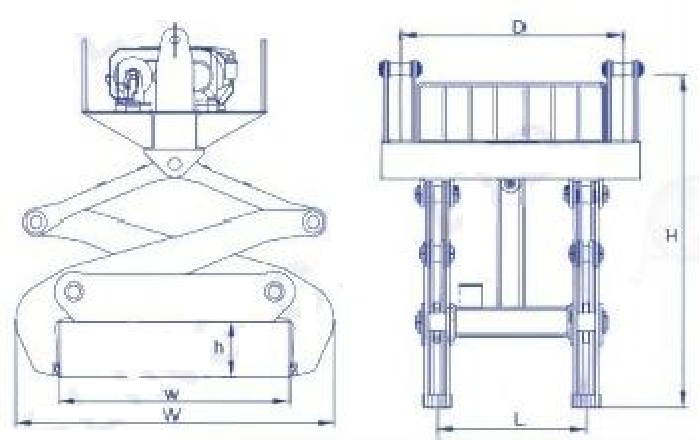

Electric Slab Lifting Clamp

■ Material Selection: Material optimization based on user requirements ensures clamp weight reduction.

■ Lever-Type Mechanism: Self-locking design with simple structure, flexible operation, and secure lifting process.

■ Self-Locking & Control: Automatic locking via load's own weight, jaw actuation controlled by winch system.

■ Customization: Customizable solutions tailored to specific slab dimensions and lifting configurations.

■ Applications: Designed for multi-layer slab handling and overhead suspension operations.

| WLL | Application scope | Height of leg | Max.dimension(mm) | Stance between lifting point | Height of leg | |

|---|---|---|---|---|---|---|

| t | W(mm) | H(mm) | W | H | mm | H(mm) |

| 32 | 1800-2400 | 1600 | 3600 | 5500 | 2400 | 700 |

| 32 | 1350-2300 | 1730 | 3500 | 4500 | 2400 | 450 |

| 50 | 1500-2400 | 1600 | 4000 | 5600 | 2700 | 750 |

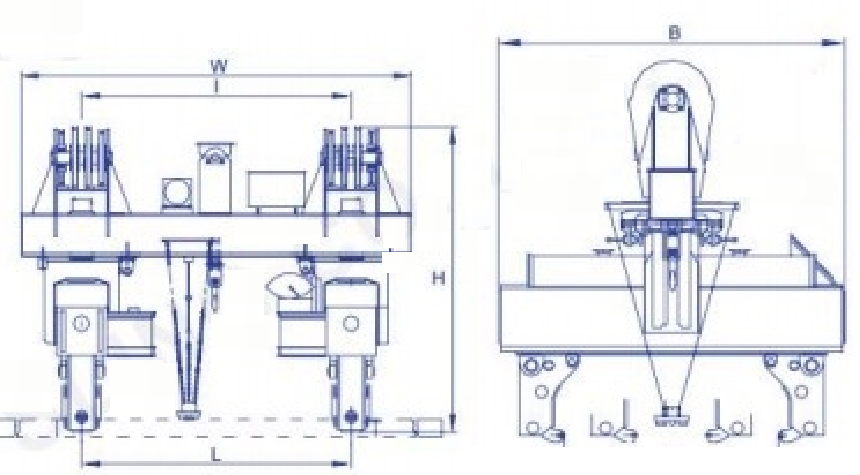

Electric Slab Translating Lifting Clamp

■ Material Optimization: Precision material selection based on user requirements to achieve ultra-lightweight clamp design.

■ Drive System:Servo motor-driven operation with ±45 wide-angle oscillation.Capable of 6-layer slab stacking.Seamless integration with crane PLC for fully automated handling (ISO 12100-2010 safety compliance).

■ Quick-Connect Interface:Modular quick-release hook coupling (DIN 15412 standard).Integrated anti-drop self-monitoring system (real-time load cell feedback, EN 13155:2003 certified).

■ Customization:Custom design is available.

| WLL | Parameter of slab | Opening degree (A) | Max.dimension(mm) | Span(L) | Distance between lifting point(I) | Height | ||

|---|---|---|---|---|---|---|---|---|

| t | size | mm | W | B | H | (mm) | (mm) | of leg(H) |

| 40 | Thickness of the slab 160-320 Length 5-12M | 750~2400 | 5500 | 4000 | 4500 | 3800 | 3800 | Max. temp. 800℃ |

| 60 | Thickness of the slab 160-320 Length 5-15.7M | 900~3450 | 6000 | 5050 | 4800 | 4500 | 4500 | Max. temp. 800℃ |

| 90 | Thickness of the sab 160-320 Length 5-12M | 900~2300 | 6000 | 4000 | 4800 | 4500 | 4500 | Max. temp. 800℃ |