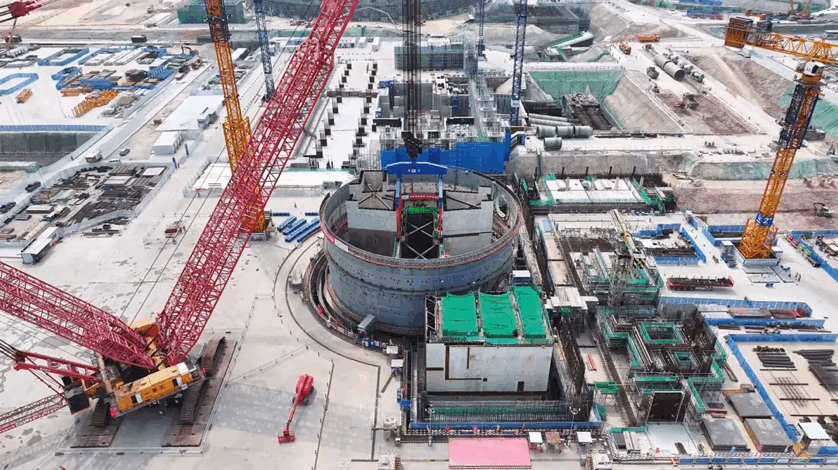

Precise hoisting and positioning of Unit 1 of the Lianjiang Nuclear Power Project Phase I by State Power Investment Corporation

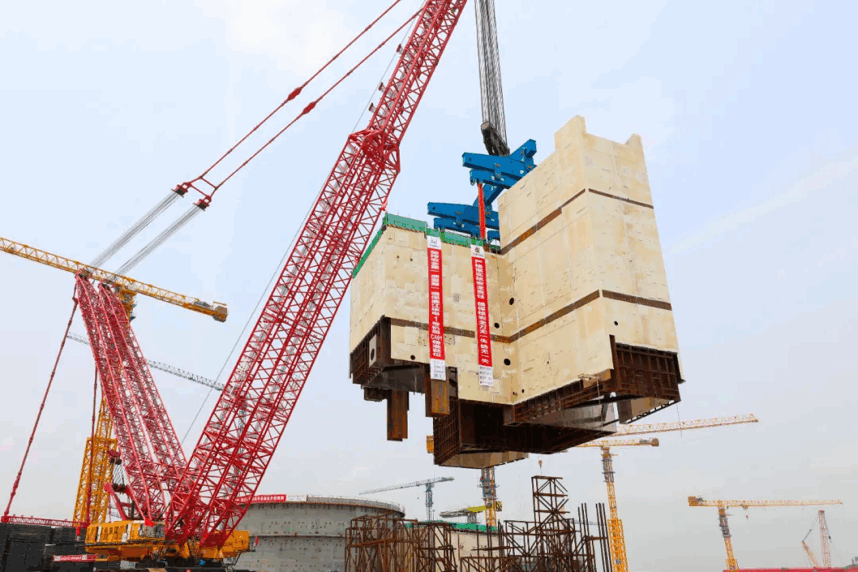

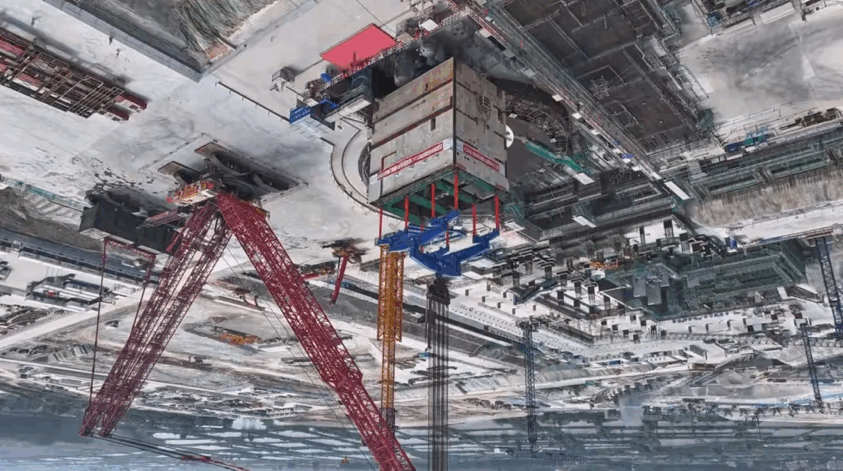

At 15:18 on April 13, 2024, the CA01 module (steam generator compartment and refueling channel module) of Unit 1 of the Lianjiang Nuclear Power Project Phase I of State Power Investment Corporation was accurately hoisted into place, creating favorable conditions for the subsequent construction of the internal structure of the nuclear island reactor building. The CA01 module with crane is located in the nuclear island reactor building, which is the installation room for the main equipment such as the reactor pressure vessel, evaporator, and stabilizer. The overall shape of the module is T-shaped, with dimensions of 29 meters in length, 26.7 meters in width, and 23.5 meters in height. It consists of 47 sub modules and has a total lifting weight of 1066 tons. The SCC36000A, which undertakes the main lifting task, is the world's first 3600 ton crawler crane and has been deployed to the Shidao Bay Nuclear Power Plant and Lianjiang Nuclear Power Plant. This is the fourth thousand ton level oversized lifting completed by SCC36000A at Lianjiang Nuclear Power Plant.

Image source: State Power Investment News Center, Nuclear America Zhanjiang Video Account

Hook 1: CA20 module hoisting for Phase I project (first thousand ton module)

Image source: State Power Investment News Center, Nuclear America Zhanjiang Video Account

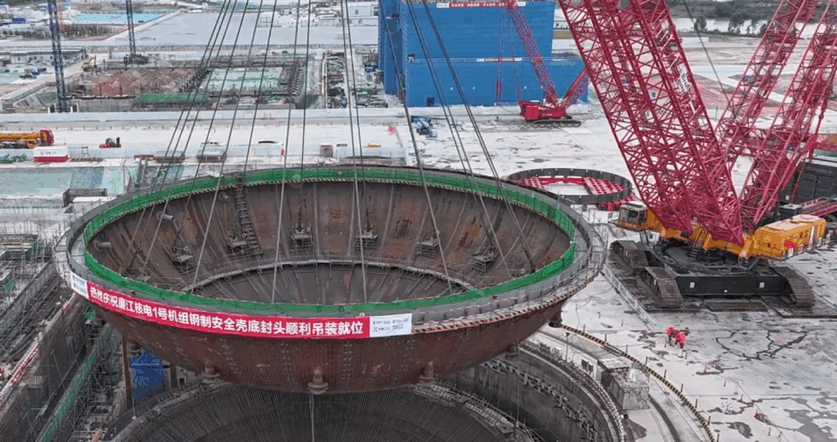

Hook 2: Lifting of the bottom head of the nuclear island containment vessel of Unit 1 (850 tons)

Image source: State Power Investment News Center, Nuclear America Zhanjiang Video Account

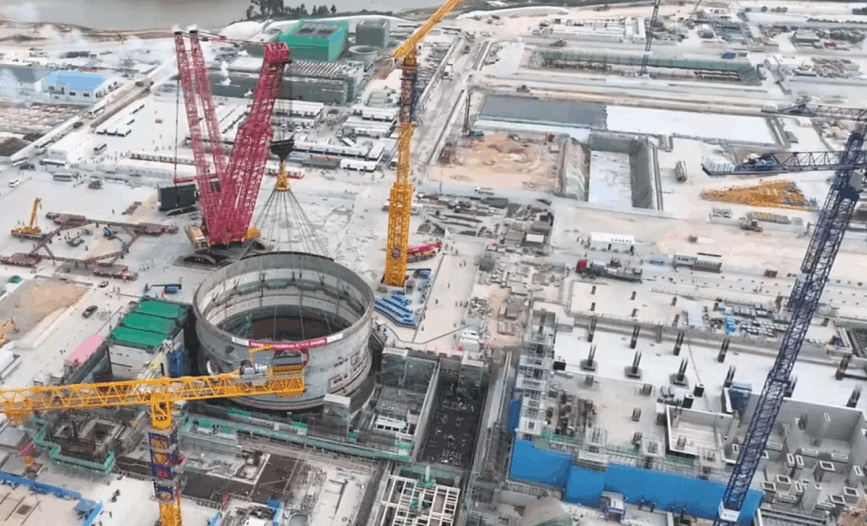

Hook 3: One ring lifting of CV cylinder of Unit 1 (1010 tons)

Image source: State Power Investment News Center, Nuclear America Zhanjiang Video Account

Hook 4: CA01 module lifting of Unit 1 (1066 tons)

Zhanjiang Nuclear Power strictly implements the requirements of "ensuring nuclear safety is foolproof and without any mistakes", "absolute responsibility, highest standards, system operation, and experience feedback", actively practices the work philosophy of "doing everything in one go", and formulates precise control measures. Overcoming the challenge of load testing for module main lifting ears in enclosed factories, advanced methods such as 3D laser scanning, simulated collision detection, and center of gravity modeling analysis are used to identify and process interfering items in advance, accurately level modules, and ultimately achieve precise module lifting and positioning.